Global Site

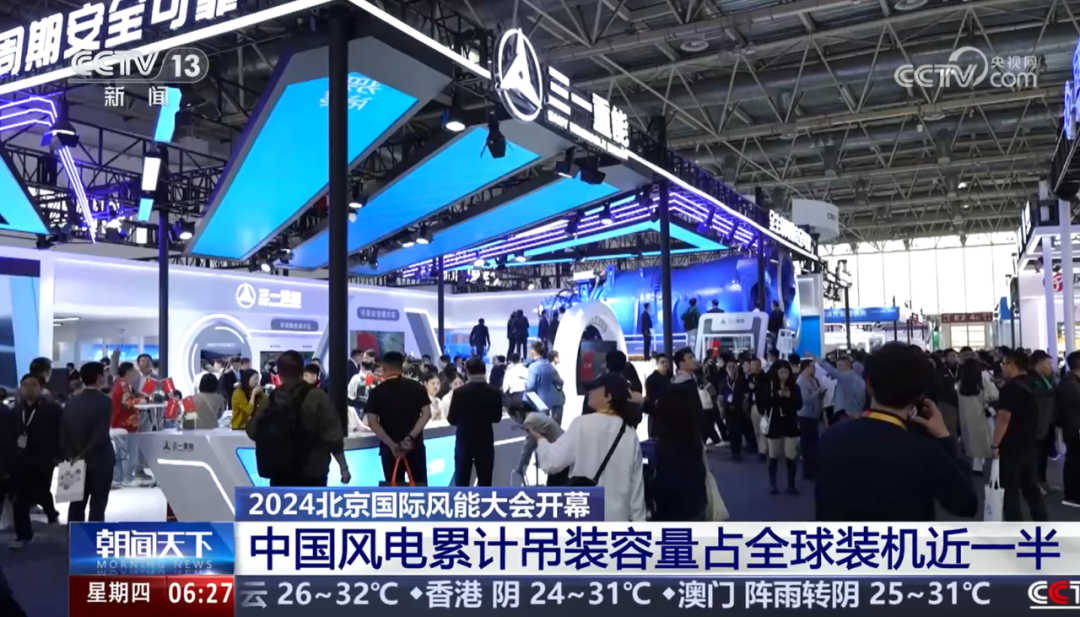

On October 16th(UTC+8), the China Wind Power 2024 (CWP 2024) officially kicked off.

SANY Renewable Energy has been prominently featured multiple times on CCTV News (CCTV13) for its "world's first wind power lighthouse factory" and "China's first 35MW Six Degrees of Freedom and Drivetrain Back-to-Back Test Bench". Under the theme of " Ensuring Safety and Reliability Throughout Product Full Life Cycle," SANY Renewable Energy showcased its comprehensive solutions that span the entire life cycle of wind turbines, including design, R&D, intelligent manufacturing, and testing verification.

During the exhibition, CCTV reporters visited SANY Renewable Energy’s Large Megawatt Wind Power Test Center, exploring China’s first and world’s largest 35MW Six Degrees of Freedom and Drivetrain Back-to-Back Test Bench, special environment simulation laboratory, and water-cooled heat dissipation system test bench. These facilities ensure the full life cycle reliability of wind turbines through a multi-level and all-process testing approach.

The 35MW test bench, independently developed by SANY Renewable Energy, is the most powerful, highly accurate, and most comprehensive wind turbine drivetrain test bench globally.

It has been custom-designed for large megawatt wind turbines, replicating extreme and complex wind farm conditions. The driving torque can reach 36 MN·m, equivalent to the driving force of 70,000 heavy-duty pickups. By accelerating the testing process, it condenses 20 years of wind farm operation into just 1 year, meeting the verification requirements throughout the full life cycle for up to 35MW wind turbines.

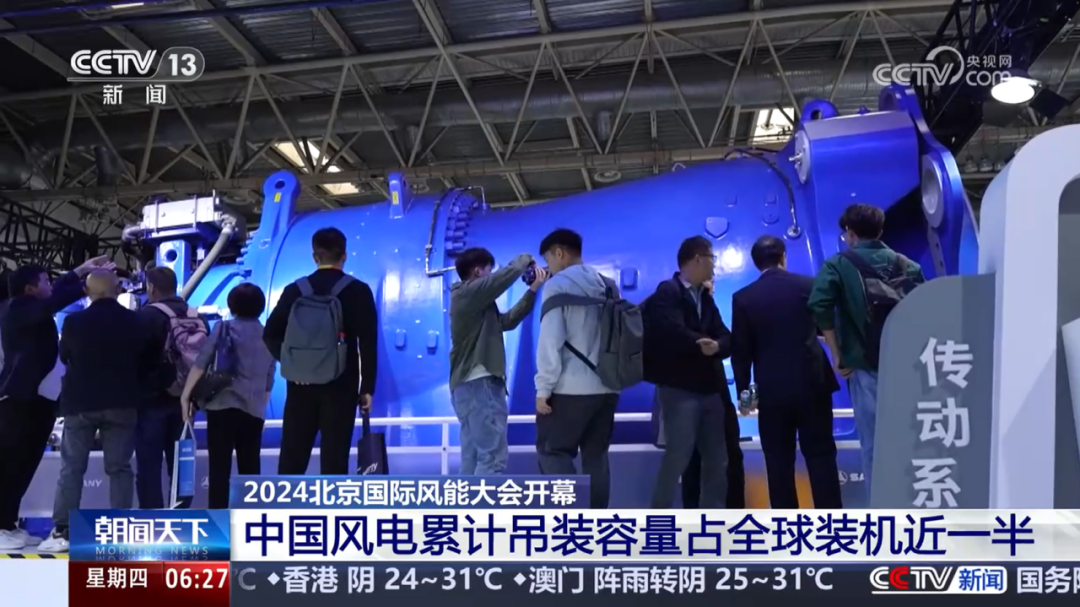

SANY Renewable Energy's 200-ton 15MW drivetrain, the only large-megawatt drivetrain exhibit at the event, made a stunning appearance on CCTV.

The drivetrain features a main shaft system with dual TRB main bearings and an integrated bearing housing, ensuring high load-bearing capacity and exceptional stability. Its gearbox uses the industry-standard front-integrated 3P1H four-stage transmission, providing a compact structure and lighter weight.

Currently, this model is undergoing extensive testing on SANY RE's 35MW Six Degrees of Freedom and Drivetrain Back-to-Back Test Bench. With an accelerated 18-month fatigue test simulating approximately 30 years of wind farm operation, this process rigorously validates both technical feasibility and product reliability.

One week before CWP 2024, SANY Renewable Energy's Shaoshan Blade Factory received the certification as the world's first wind power industry "lighthouse factory". CCTV reporters visited the factory to unveil the mysteries of this "super blade factory" to the world.

The Shaoshan Blade Factory employs an industry-first digital twinning platform, creating the factory's "smart brain." With just an iPad, operators can monitor all operational conditions and production data in real-time, achieving 360-degree online monitoring and lean management of the entire production process. By utilizing robots combined with laser-guided technology, the factory automates various processes, including the automatic polishing of blade surfaces, large-scale automatic painting, and on-demand material distribution, enhancing production efficiency by 33% and improving product quality by 20%.

At the exhibition, SANY Renewable Energy received certificates from several authoritative international certification organizations, including TÜV Rheinland (Germany), the China Quality Certification Center (CQC), UL, and DNV. This achievement signifies that SANY Renewable Energy's product technologies strictly meet both international and domestic safety and performance standards.

By obtaining this series of authoritative certifications, SANY Renewable Energy not only strengthens the safety and reliability of its products but also gains strong confidence to deeper enter into international markets. This accomplishment highlights the company’s commitment to deepening its roots in China while enhancing global exploration of wind power industry.

On October 17, during the Green Transformation and High-Quality Development session at CWP 2024, Paulo Fernando Soares, Managing Director of SANY RE Europe, delivered an impactful speech on behalf of SANY Renewable Energy.

As one of the top 5 global wind power manufacturers, SANY Renewable Energy continues to lead the way in driving sustainable development through cutting-edge technological advancements.

In 2023, SANY RE launched the world’s largest onshore 15 MW wind turbine, which was successfully installed last week. To ensure the reliability of large-megawatt turbines, SANY RE independently developed and designed the 35MW Six Degrees of Freedom and Drivetrain Back-to-Back Test Bench, the world’s most powerful, accurate, and comprehensive drivetrain test bench. These accomplishments fully demonstrate SANY Renewable Energy's exceptional strength and commitment to developing high-quality products and advancing technological innovation.

Furthermore, as Paulo highlighted, through digital transformation and efficient energy management, SANY RE has significantly accelerated the development and utilization of renewable energy. For example, rooftop photovoltaic installations were completed at Nankou Industrial Park, Shaoshan Blade Factory, and Chenzhou Industrial Park, covering a combined area of 111,331 square meters with an installed capacity of 15.28 MW. Additionally, the company actively engaged in green electricity trading, with Nankou Industrial Park purchasing 3,804.58 MWh of green electricity in 2023.

On the first day of the exhibition, Yu Liangwei, General Manager of SANY Renewable Energy Marketing Company, was invited to attend the opening ceremony of CWP 2024, witnessing the kickoff of this annual wind energy event.

During the event, SANY Renewable Energy's self-developed 15 MW onshore wind turbine was awarded the "Innovative Model" prize by CWP. This turbine, which is the largest single-unit capacity wind turbine installed globally, marks another milestone in the development of large-scale wind turbines in China. With a design lifespan extended to 25–30 years, each unit can generate enough electricity to meet the annual needs of 160,000 households.