Global Site

On October 15th(UTC+8), China's first and the world's largest 35MW Six Degrees of Freedom and Drivetrain Back-to-Back Test Bench was officially put into operation at SANY Renewable Energy's Wind Power Testing Center.

On October 15th(UTC+8), China's first and the world's largest 35MW Six Degrees of Freedom and Drivetrain Back-to-Back Test Bench was officially put into operation at SANY Renewable Energy's Wind Power Testing Center.

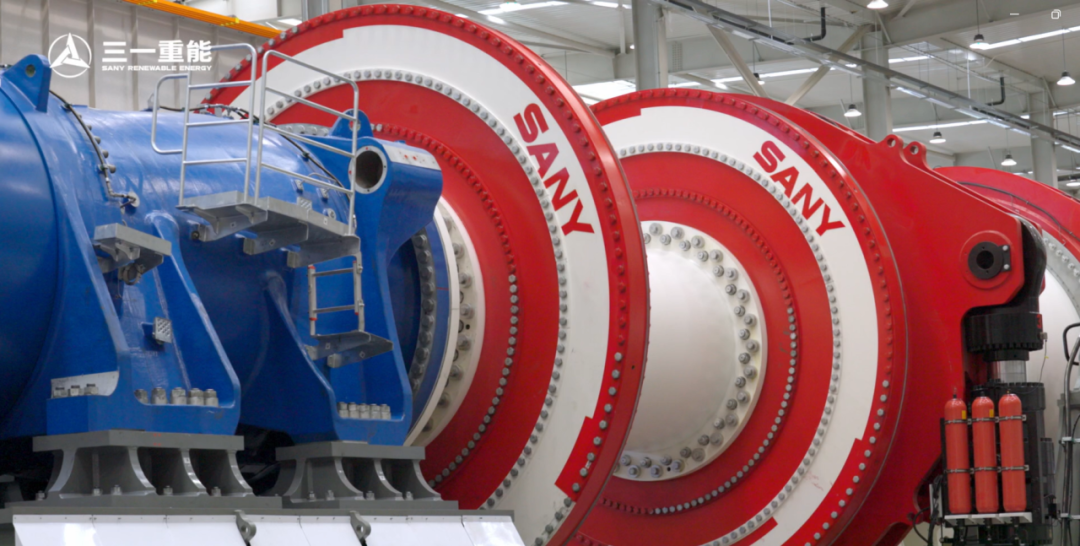

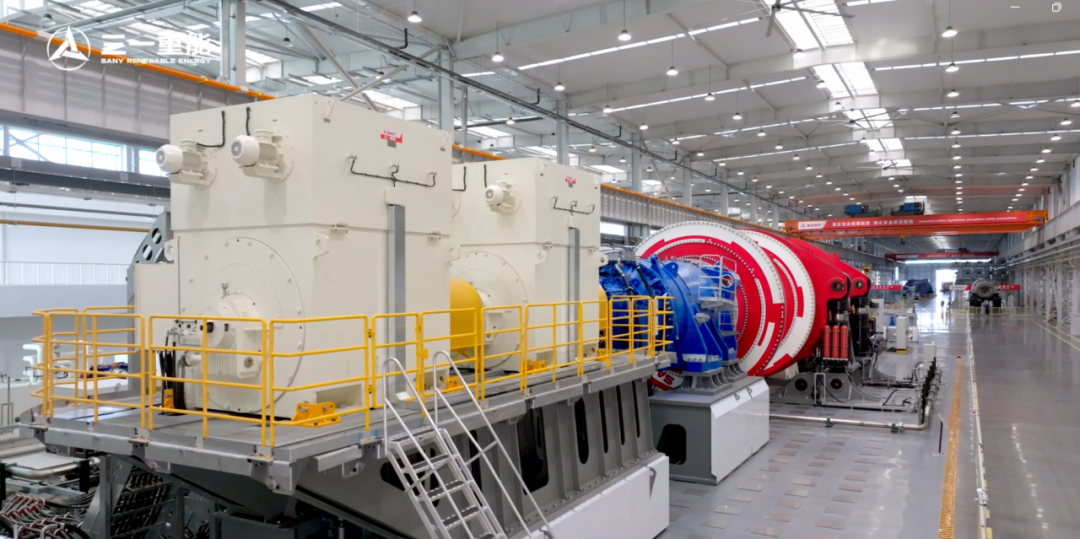

This test bench, independently developed and designed by SANY Renewable Energy, utilizes a 100% domestic supply chain. It is the world's most powerful, highly accurate, and comprehensive wind turbine drivetrain test bench, capable of simulating the full lifecycle of wind turbines up to 35MW, paving the way for future large-scale wind power advancements.

As wind turbines increase in size, handling these massive, hundreds-of-tons machines requires simulating complex, large-scale, multi-degree-of-freedom forces and adhering to stringent verification standards. This significantly increases the difficulty of designing and constructing such test benches.

So how does SANY Renewable Energy's 35MW Six Degrees of Freedom and Drivetrain Back-to-Back Test Bench address these challenges?

In real wind farms, wind conditions are constantly changing, and the loads on wind turbines are complex and varied. Traditional test platforms can only apply loads in a single direction, making it difficult to simulate real-world forces and achieve accurate test results.

The 35MW test bench uses six 100-ton hydraulic cylinders to apply multi-directional, coordinated loads across six degrees of freedom, allowing for extreme, multi-axis stress testing. With a maximum driving torque of 36 MN·m and a bending moment of up to 80 MN·m, it accurately simulates complex weather conditions and extreme working environments. This ensures the turbine can withstand typhoon-level winds and other severe conditions.

By utilizing high-intensity accelerated fatigue tests, the test bench simulates 20 years of wind farm operation in just 1 year. It can simultaneously perform functional tests, failure limit verification, and design model validation on the entire turbine and the key components like generators, gearboxes, and main shafts. This thoroughly verifies design feasibility and product reliability while exploring technological boundaries and physical limits.

With thousands of sensors monitoring the entire testing process, real-time data collection feeds back into product design to refine digital simulation models, creating a closed-loop system from testing to optimization that ensures the reliability of wind turbines throughout their lifecycle.

The successful operation of the 35MW Six Degrees of Freedom and Drivetrain Back-to-Back Test Bench is a testament to the dedication of China's wind power industry in pushing technological boundaries. SANY Renewable Energy remains committed to safeguarding the sustainable and high-quality development of the wind power sector, creating a sustainable future.